Preventative Maintenance Software

-

What is a preventative maintenance program?

-

How do I create a preventative maintenance program?

-

How does preventative maintenance software benefit my organization?

What is a Preventative Maintenance Program?

A preventative maintenance (PMs) program is a listing of required maintenance tasks linked to one or more equipment items. The purpose of PMs is to extend equipment life and increase equipment reliability.

The best way to manage a preventative maintenance program is with a CMMS software program. By doing so preventative maintenance are issued, closed and archived for later review and analysis. The result of capturing this history leads to better resource allocation, including personnel labor and spares use.

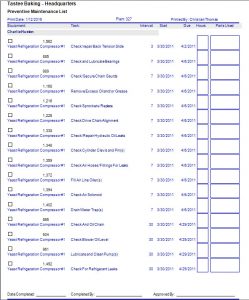

In many cases assigned PMs consist of a simple checklist. Other situations call for more detailed lists of tasks, equipment, detailed instructions, linked documents and spare parts lists. MaintSmart CMMS answers to call on all of these PM list possibilities. Perform preventative maintenance with the work order system or the unique calendar-based PM system found only in this CMMS.

How Do I Create a Preventative Maintenance Program?

There are two different ways to create a preventative maintenance system in MaintSmart. One way would be to simply use the work order system with work order templates linked to schedules or meters and have new work orders of a preventative maintenance Type created automatically as required. With this method each work order would contain one equipment item and one task. Of course the maintenance planner would likely include extensive task details into each work order too. These details usually represent the sequence and procedure for completing this PM work order. By using work orders for preventative maintenance the maintenance program has full benefit of all of the work order features such as file attachments, multiple mechanics on one job and much more.

Conversely this CMMS has a extra module specifically for calendar-based preventative maintenance (PMs). This CMMS software is the only one that contains this powerful but simple to use module. Unlike the work order system with this PM system PMs are created one time then rolled over when closed with a new start and due date. many or all PMs may be selected and closed all at once and PM assignments are automatically scheduled and issued at exactly the right time.

In conclusion use either the work order module or the preventative maintenance module for your PMs, or use both!

How Does Preventative Maintenance Software Benefit My Organization?

Preventative maintenance software benefits your company by maintaining a structured and comprehensible way of maintaining equipment with the goal of circumventing failures and prolonging equipment life through recommended maintenance procedures.

Stated another way a PM program helps your company avoid unexpected downtime and prolongs equipment life. This should always be the goal for a maintenance operation rather than focusing on repairs after equipment has failed. With this in mind MaintSmart CMMS answers the call in the following ways:

- Use either (or both) detailed work orders or the unique list format for PMs.

- Automatically print or email PM task lists to mechanics at exactly the right time by using the print scheduler.

- Maintain compliance with PM completion requirements by utilizing the extremely simple and fast calendar-based PM module.

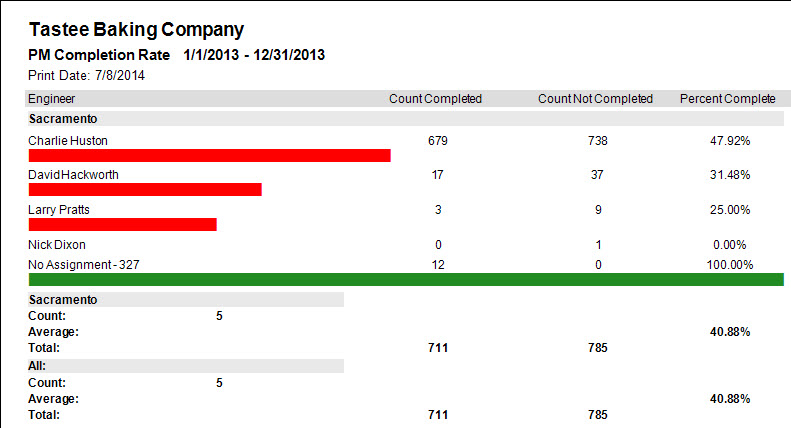

- Analyze and report on PM labor, parts and late PMs in seconds.

- Report on the complete cost to maintain equipment with practically no effort.

- Let the CMMS Reliability Analysis module suggest preventative maintenance task intervals based upon MTBF.

Preventative Maintenance Software (2:06)

Preventative Maintenance Software Work Scheduler (9:00)

Preventative Maintenance Percent of Completion Report

PM Task List (Compact Format) One of Five Available Formats