Enterprise CMMS Software | EAM Software

Enterprise CMMS Software

Enterprise CMMS software is designed to manage all the maintenance management needs of any organization. A good enterprise CMMS like MaintSmart scales easily as your organization grows. This software could be described as an EAM software or enterprise asset management software system. MaintSmart users counts range for single users to hundreds of concurrent users. Additionally a good enterprise software system is designed to manage all facets of its designed use. MaintSmart accomplishes all these goals by providing enterprise level components as follows:

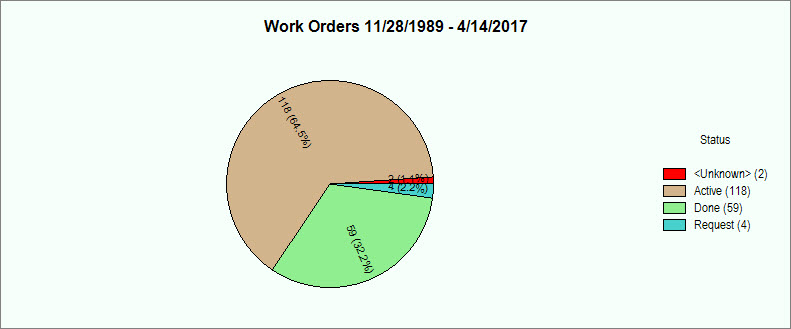

- Complete work order management system.

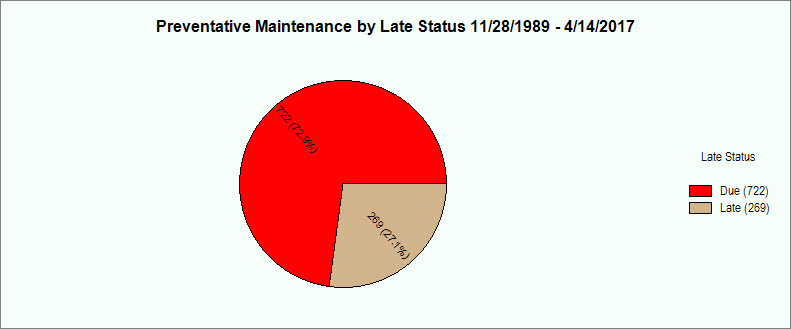

- Preventative maintenance software module.

- Full purchasing software system including: requisitions, role-based approval management, purchase order management, invoice matching.

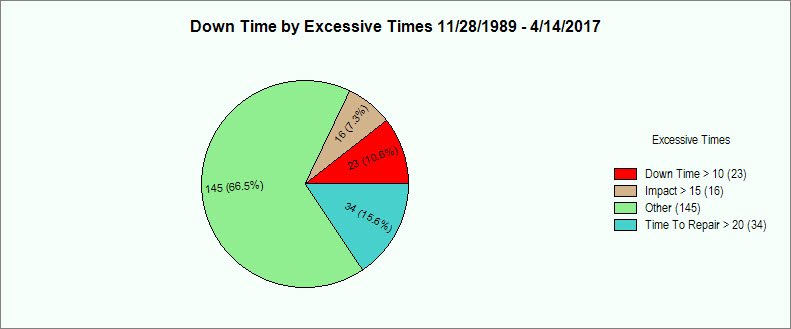

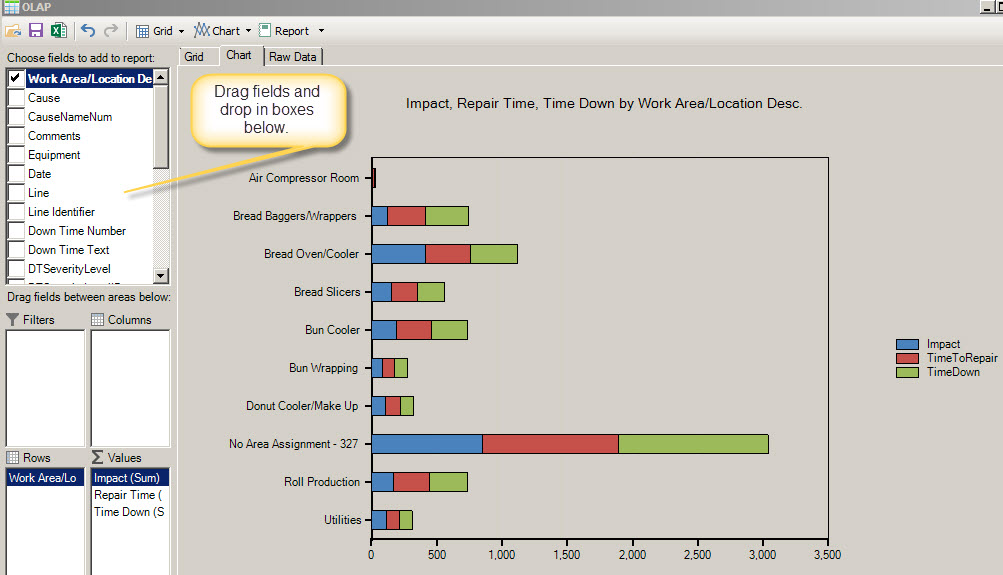

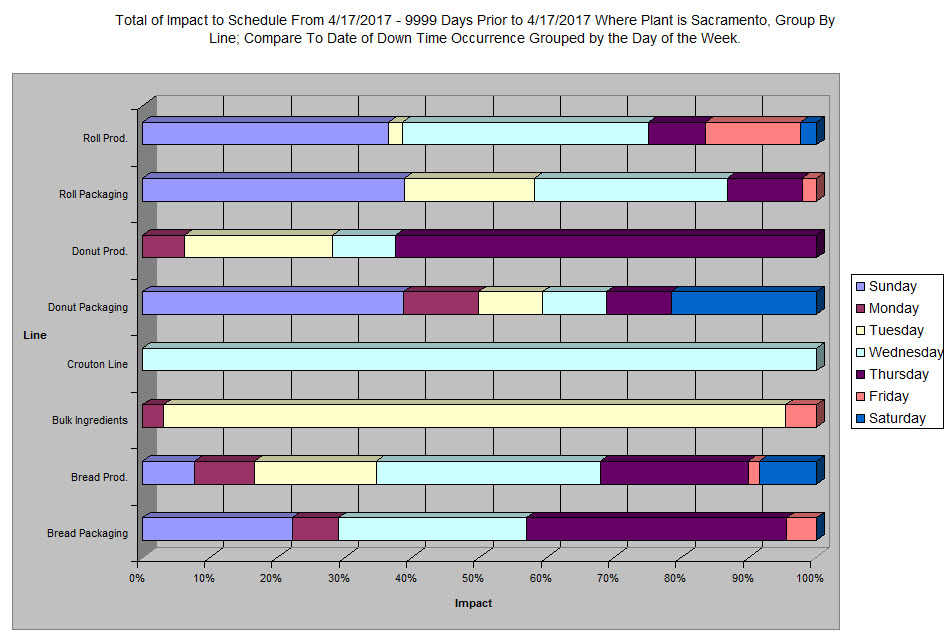

- Extensive downtime and equipment failure logging with powerful analysis tools to optimize your maintenance management program.

- Informative and flexible analysis and CMMS reporting on all the above listed components.

All the above is further leverages with flexible reporting of ALL DATA in the CMMS. Over 300 report templates included. Query designer with drag and drop builds any report and chart needed with no limitations. All data exports directly to Excel. All data may be instantly converted to a web page with two button clicks.

Reporting to printers or email is simple and consistent. Additionally reporting with the use of floating date ranges guarantees the exact report at the right time with exactly the right data included.

With a user-defined equipment hierarchy and complete translations available in any language this enterprise CMMS is favored by organizations and governments in 41 countries as of 2017. Much of our success is due to our international CMMS resellers and their dedication to supporting international users.

Enterprise CMMS Provides a Complete Query-Builder and Reporting Tool

Enterprise CMMS Exports to Excel

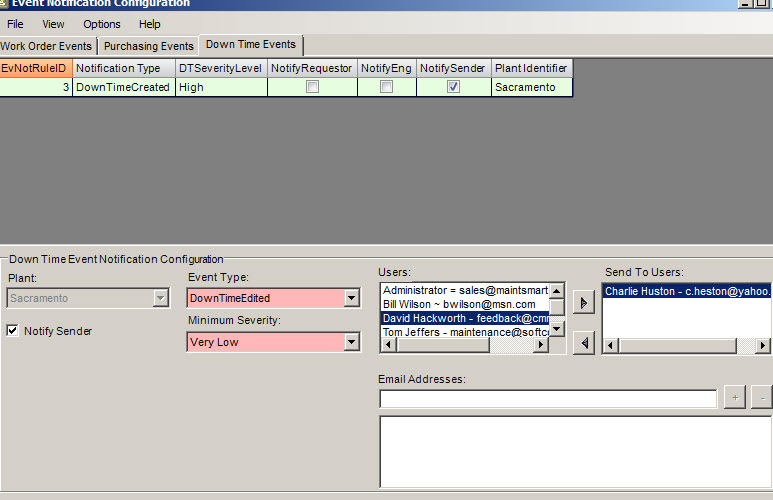

Event Notification for Various Important Events

Three Dimensional User-Defined Equipment Hierarchy

The three dimensional equipment hierarchy is unique. This design provides a way for you to group equipment the way you need to see it. Best of all the nodes of the hierarchy may be configured so that levels may be not directly bound to another level. This lends itself to the ability to have the same equipment associated with two completely unrelated levels in the hierarchy. For example consider a commercial baking operation where equipment (Bread Oven #1) needs to be associated with a Process (functional location) but also with a Building (geographical location). In this example Bread Oven #1 may be reported on as part of the Bread process as a whole but also reported on as equipment in Building #100 (for example) even though this oven runs through Building #100 and Building #101.

Below are a few examples of equipment hierarchy diagrams used by MaintSmart users. Keep in mind the naming of these levels may be changes in seconds so we encourage you to try different naming conventions until you find the best on for your maintenance management application.

Manufacturing Facility

Manufacturing facility (plant) equipment hierarchy.

Building Equipment Hierarchy

Building (facility) maintenance equipment hierarchy example.

Oil Rig Platforms

Oil rigs owned by different owners. Managed by one maintenance company.

Wind Farm Equipment

Wind farm equipment maintenance system hierarchy example.

College or School Equipment

College, university or school equipment layout for the equipment hierarchy.

Equipment Hierarchy for a Resort

A possible resort equipment hierarchy design.

Download MaintSmart 5.0

Full MaintSmart 5.0 CMMS Software for 30 Day Trial.

Equipment Hierarchy

Learn how to set up the equipment hierarchy and create equipment items.

Preventive Maintenance Scheduler (advanced)

Learn how to scheduler PMs and reports.

The CMMS dashboard provides a quick view of priority work orders, preventative maintenance, purchasing, spares levels and equipment downtime. This is an interactive dashboard with reporting capability.